Solutions for the packaging industry

Reliable and durable

- Slip rings: from standard to custom

- Incremental and absolute rotary encoders

- Displays, counters and process controllers

- Ideal for the most stringent hygiene requirements

- High degree of protection, stainless steel variants

Maximum system efficiency with Kübler products.

A high yield under efficient production conditions is crucial for the economic operation of modern production facilities in the packaging industry. Key factors to the economic efficiency of production are: Increased plant performance by accelerating individual processes, optimized control of production orders and minimization of downtimes. Kübler has offered suitable products for this purpose for years, which renowned manufacturers of packaging machines, rotary indexing tables or filling plants use. From encoders to linear measuring systems and slip rings to counters and process controllers. Regardless of which product you choose – every single one of them meets the high requirements of the food industry and is thus the ideal solution for your plant.

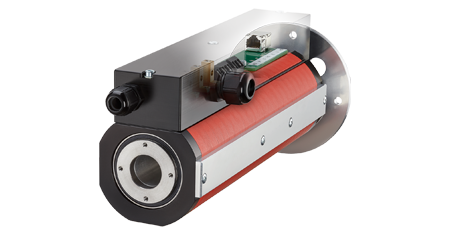

Slip ring SR060E – the flow pack specialist. NEW: Plug and Play dank Easy Connect Modul

Ideally suited for the heating of sealing rollers. Specially developed for this task, the Kübler SR060E slip ring has been used by leading manufacturers for years and has proven itself to be a reliable and durable solution for transmitting load and signals.NEW: The SR060E is now available with the Easy Connect Module, a pre-wired connection cap with connectors. Without time-consuming wiring, the slip ring can be quickly and safely integrated into the system on site thanks to reverse polarity protection. Replacement can also be easily carried out via "plug and play".

- Compact design – space-saving

- 3 load and 2 signal transmissions – reliable

- Innovative contact technology, no oils needed – low-maintenance

- High degree of protection, smooth surfaces – easy to clean

To the compact slip ring SR060E

Transmission of power, signals and data with modular slip rings

Carousels are used in highly-dynamic plants for various process steps. Each carousel must be supplied with power and be connected to the control system accordingly. Kübler slip rings are the ideal solution. They stand for a reliable transmission of power, signals and data. When combined with a media lead-through, fluids and gases (hydraulic and pneumatic) are also transmitted.Positioning and speed monitoring with optical encoders and linear measuring systems

Safe, quick, versatile and compact – properties that make Kübler encoders particularly ideal for use in packaging machines. The sturdy bearing structure in the Safety-Lock™ design with extra-strong outer bearings increases the lifespan and avoids machine downtime and repairs. Numerous ordering options, such as connection and fastening options, allow for a flexible and universal use. Linear measuring systems and custom measuring wheel systems are available to you for monitoring linear movements.Detecting, controlling and visualizing with counters and process controllers.

The powerful and very easy to operate Codix preset counters allow for decentralized, low-cost control systems, from simple unit quantity counting to controlling welding seams. The compact Codix displays serve to visualize, for example unit count, time or temperature, directly at the site of occurrence.Your application is our priority

We are happy to take on custom challenges. Describe your application to us. Together we will find the right solution. We look forward to your inquiry.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.